|

Wire Wrapped Jewelry

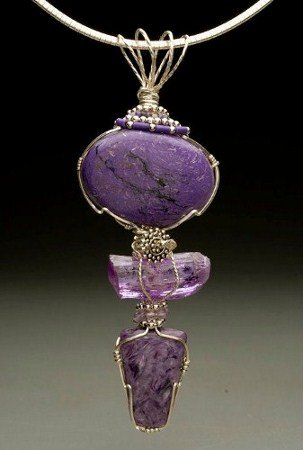

So what exactly are we referring to when we say, "Wire Wrapped Jewelry"? Jewelry wrapped with wire ranging from a thick 10 gauge to a super thin 34 gauge. Also findings (clasps, ear wires, jump rings, head-pins and bales ) are used. Some consider settings for the stone as findings also. There is no soldering or heating the wire. In other words, all connections are of mechanical means such as bending. And we like to differentiate wire wrapped jewelry from handmade wire jewelry. Not to confuse “wire wrapped jewelry” with “handmade wire jewelry” which for our purposes, may be soldered and otherwise sculpted. Checkout our page on handmade wire jewelry here. History of Wire Wrapped JewelryWire wrapped jewelry has been around a long time, like since 2000 BC. Someone found a twisted peace of wire from the Sumerian dynasty and Archaeologists figured it was jewelry. Then came the ancient Romans around the time of Christ. British museums have loops dated 2000 years ago. Loops are a very important part of the whole wire wrapped jewelry craft. The ancient jewelers used gold, silver and copper. Superb metals for handmade fashion jewelry. It was hammered very thin and then cut into strips, then hammered and filed into wire, “by hand”! How long do you think that took? This is called filigree. Wire wasn’t drawn until around the 8th century somewhere in France. It wasn’t until around 1270 AD, France also, that the first commercial wire foundry started to operate. Back in the day solder did not exist. Everything was wrapped in a manner that would suit the intended function. “P” loops and “eye” loops were developed and before you know it one of the oldest art crafts was born. So you might say the development of wire wrapped jewelry started then and has become what it is today. WOW!!! Bye the way, even after solder became available, wire wrapping stayed popular because it was more economical. Soldering is faster though, which is why machines work so well in what should otherwise be a handmade craft, if you get my drift. And that’s why hand wrapped jewelry is truly a fine art form. Material: The wire used in wire wrapped jewelry comes in a variety of shapes. There is round of course but also square, twisted, half round and flat. The metals are the same as history provided. Gold and gold fill, silver and silver fill, copper, brass, and sterling silver. Did you know that sterling silver is 92.5% silver and 7.5% alloy metal, usually copper. 100% Silver, like gold, is very soft and could fail in stress applications. Equipment: Some other tools and equipment that will make your day go easier are; a chasing hammer, hammers of steel or brass with a large face. This helps keep the edge of the hammer from marking the wire, a nylon hammer, this doesn’t flatten the wire itself, an anvil, not too big, a cup bur, this tool puts the finishing touches on the wire and your work. They also make nylon jaw pliers, step jaw pliers and loop closing pliers. The step jaw pliers allow you to make loops in different sizes quicker. If you were making a lot of them this would be a very handy tool for sure. And don’t forget a steel ruler. A ruler will come in handy more times then you might think.

Now, for the artists to be. Basically to make your affordable handmade jewelry, or perhaps handmade gifts, you only need the first four tools. The round nose pliers the chain nose pliers the bent chain nose pliers and a good flush cutter to try out this art and they won’t break the bank either. Start out small and see if you like it and who knows? Some day you may be customizing your tools like the professionals’ do. A little grind here a little grind there and before you know it your tool is perfect. And it does what you tell it to do every time. They also make various jigs you can use. These are handy if your making wire wrapped jewelry that has a lot of coils or S designs. Actually, jigs would have many uses in forming wire and would not put marks on the wire itself. There again making for a cleaner piece of work. Now, we’re not getting paid to tell you this but there is a web site called wigjig/jewelry-making and they have a large selection of tools and equipment, prices range from starter tools $15 to professional grade where a bent chain nose pliers could be $50 or so. Nice site. So what are you going to wrap? The possibilities are endless. Polished stones are high on the list and make for some awesome handmade gemstone jewelry. Gem stones, precious and semi precious, agate and jasper, gold nuggets, old coins, lockets, heirlooms, meteorites the list goes on and on. Lets go with polished stones. The selection is huge, and the work, when finished, is incredibly satisfying and makes for beautiful handmade jewelry designs. At the art shows the wire wrappers attract quite a crowd. Some of them will wrap right there at the show. That can be very educational to the new comer or the hobbyist to this art. You should check out a “Lapidary” first. A lapidary is a stone collector basically. They have the knowledge about the stones and can guide you on your way. When going through the stones you like, don’t be afraid to choose ones that have small faults in them as you can high light these faults and end up with a more exciting piece. Turquoise and many of the hundreds of jaspers have these small inconsistencies that can put the “awesome-ness” into your work! And like the tools and wire, most of these stones aren’t that expensive. The stones and wire for a pendent and earrings in turquoise would cost between $15-$25. Now don’t get me wrong, you could spend $100 too, but start out a little smaller and surprise yourself just the same. What drives the cost of this work in the end, is craftsmanship, experience, and quality. Brothers Handmade is not a tutorial site, exactly, but we do like to get your feet wet in the different craft-arts. Having said that check out this video to wet your whistle a little more. Wire wrapped jewelry is an ancient and incredible art form. Go to juried art shows to see it first hand, then come to and meet these artist craftsmen and just maybe they will have some work hidden away that they will share with you. Well let’s just say I know they will share with you. |

Appreciate when you ...

What's New on BH?

Blog: Old Fourth Ward - Atlanta, GA

Feature: Potter - Julie Jones

Store: Paintings by Carol Benner

Editor Picks from Store

|

|

|

| Lavender Painted Soap | Volcano Dangle Earrings | Footed Coffee Mug |