|

The Pottery WheelArchaeologists have discovered remnants of ancient pottery wheels and ceramics thrown on a wheel dating as far back as the late Neolithic period (New Stone Age) around 8000 BC. Find more information on the History of Pottery, right here. The Pottery Wheel was used for mass-producing pottery between the years of about 700 BC to the 1700’s (AD). In the late 1700’s slip casting took over as the most popular means of ceramic mass production. Slip casting involves pouring ceramic slip into molds. The original pottery wheels were slowly turned by foot or hand as the craftsman worked primarily on coil pottery. Later versions included the use of a heavy flywheel that stored energy and sped up the clay forming process. Typically the Potter first places a disk of wood, plaster, or plastic on the wheel head. This protective piece is called a bat. After formation of the clay object, the bat is lifted off with the newly formed piece intact. This protects the piece from distortion. After the bat is in place, the next step is to form a ball of clay, place it on the wheel, and then begin the process of Centering the Clay. This Centering step can be somewhat difficult to master, but is essential prior to forming the clay. Watch the short video and see how Deborah Slahta’s Centering technique accomplishes this initial step.

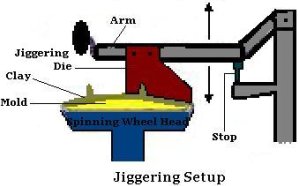

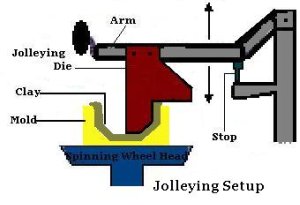

During the process of "throwing", the pottery wheel rotates quickly while the ball of soft clay is pressed, squeezed, and pulled gently upwards and outwards into a hollow shape. Referred to as “Opening” the clay, the Potter carefully makes a centered hollow in the spinning ball of clay. She will also perform the flooring step, which is ensuring proper thickness, and making the flat or rounded bottom inside the pot. After this the Potter begins the “Throwing” step (see the origin of the word “throwing” below) when they draw up and shape the vessels walls to a consistent thickness. After this they will perform a trimming and turning process to remove excess clay and refine the shape of the vessel. The newly formed clay piece can be further altered and decorated using a variety of tools and techniques. For information on many of the tools used, see our Pottery Tools and Supplies page. Some of the finishing alterations include: bulging, carving, fluting (making scalloped cuts with a fluting tool), faceting (cutting flat surfaces), incising (depression made into the wet pottery with a sharp or pointed object) and by other methods making the clay formation more interesting. Often, thrown pieces are further modified by having handles, lids, feet, spouts, and other functional aspects added using the techniques of handworking. So now back to the origin of the word “Thrown” as it pertains to pottery. Dennis Krueger explains in an article found in Ceramics Today that "Thrown Pottery" comes from the Old English (500-1050 A.D.) word "thrawan" which means to twist or turn. So it's not the act of hurdling a lump of clay through the air toward the pottery wheel, but rather to twist and turn that clay to form a creation. Jigger and Jolley Used since the 1700’s, both Jiggers and Jolleys require a mechanical arm on a hinge typically attached to the frame of the pottery wheel. The arm has a die or profile template attached which is often made of metal. This die is lowered down on the surface of the clay while the clay is spinning, and creates a uniform shape on the spinning wet clay.

Jiggering is commonly used to make identical items such as plates and shallow bowls. Clay is laid on top of a mold spinning on the wheel. Jolleying is similar to a jiggering. The difference is that with a jolley, the clay is placed inside the mold rather than on top of the mold. A jolley is a die or profile template that when lowered onto the clay, cuts away the inside of the clay typically forming a vessel such as a cup or deep bowl. Jolleys and Jiggers are mostly used in mass manufacturing where uniformity is more important and operator artistry or skill is less important. You won’t find jiggers and jolleys very often in artistic ceramic studios. But on occasion you will.... |